From the original idea, through to the end product

Rotolia studies, designs and manufactures plastic parts and components, all with comprehensive management. We take care of the whole process. From start to finish.

Thanks to our use of cutting-edge technologies, we develop innovative ideas and transform them into products tailored to the needs of each customer.

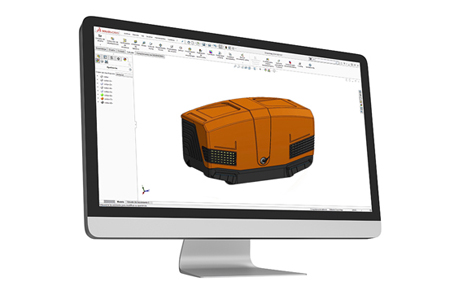

1. Design experts

We have a technical office and studios specialising in product design, carefully planning the best solutions in line with our customers’ requirements.

We create 3D designs to define the characteristics and details to be manufactured later on.

2. Prototypes

Thanks to 3D printing technology, we transform our customers’ ideas into physical parts. We build a 3D prototype to evaluate, alongside the customer, the characteristics of the product in this initial phase, ensuring improvements right from the outset.

Prototyping is a methodology that has evolved and progressed over the last 30 years. It has led to the manufacture of increasingly productive, efficient materials, providing a highly advanced design and development process.

A prototype is an initial mould or sample in which a part or product is manufactured. 3D part prototyping is fast and also less expensive. Some of the advantages of 3D prototypes are:

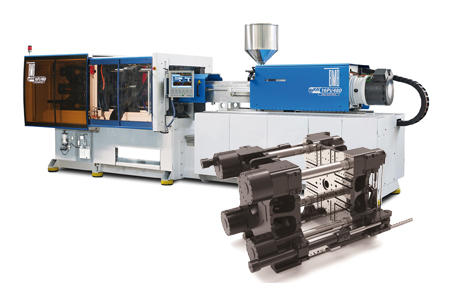

3. Moulds and manufacture

Our use of the most competitive mould tooling on the market combined with cutting-edge technologies allows us to produce a mould that will ensure the best possible product during manufacture. Whatever the thermoplastic technology used, we design the moulds according to the customer’s production requirements, quality and needs.

At Rotolia, we manufacture under quality standards ISO 9001 and ISO 14001, based on continuous improvement and clean production as a way to cut costs, waste, and time. We monitor manufacturing parameters to ensure the highest final quality.

4. Logistics and packaging

At Rotolia, we can assemble elements in the pieces manufactured, labelling and bagging the products with corporate packaging and shipping them to their final destination. In other words, we provide customised assembly for all parts, packaged for safe shipment to the customer.

Contact us

Use the form for any questions you may have about manufacturing techniques, quotes or delivery times, and our technical office team will get back to you at the earliest opportunity.

Data controller:ROTOLIA PLASTICA S.L. / Tax number (CIF): B98737026 /Address: P.I. Mediterráneo – C/ Fila 6, 46550 Albuixech (Valencia) / Email to exercise rights: [email protected] / Telephone: 961 204 910

Main purpose: To answer queries and provide the information requested. To manage the potential commercial/professional relationship.

Rights: Access, rectification, erasure and portability of data, limitation and opposition to its processing, and to not be subject to decisions based solely on the automated processing of data, where appropriate.

Additional information:Additional detailed information about our Privacy Policy can be found in this section.

FAQ

Find answers to questions about Rotolia and how we work.

We use the four most widely used thermoplastic technologies in the industry: Injection moulding , rotational moulding, thermoforming, and blow moulding.

Yes, we advise customers on the most suitable technology according to their requirements and the manufacturing units they need.

Yes, Rotolia handles the entire process. From the original idea, through to the end product. Rotolia studies, designs and manufactures your plastic projects with cutting-edge technologies.

Customers can choose whether they prefer comprehensive product management or would rather take care of the final packaging themselves. Rotolia can take care of any products requiring assembly of parts or other elements. It can also take charge of labelling and bagging the product with the customer’s corporate packaging, ready for shipping to the final destination.

Yes, of course. We respect our planet, and are ahead of European regulations on waste management. All of our production has been 100% recyclable since 2018. We also work with natural additives, and collaborate with the Upcycling The Oceans Foundation to give new life to plastic materials.

Yes, at Rotolia we work for the automotive industry, urban furniture, interior and exterior decoration, agriculture...