Rotolia designs and manufactures industry-wide plastic parts

We have a highly qualified multidisciplinary technical team to give shape to your ideas.

We use some of the best known thermoplastic technologies, and are specialists in rotational moulding, injection moulding, thermoforming, and blow moulding.

Comprehensive management

We develop innovative ideas, and transform them into products tailored to each customer.

Technologies

Manufacture of custom-made parts and components with four technologies: rotational moulding, blow moulding, thermoforming, and injection moulding.

Multidisciplinary team

Technical office with experts in design, quality and production.

Guaranteed quality

Products that stand out thanks to their finishes and quality.

We shape your ideas and mould your projects

We will advise you on the thermoplastic technology most suited to your requirements: manufacturing units per year/month, mechanical, chemical and aesthetic characteristics. We can offer this service thanks to our highly skilled team.

Our headquarters are in Valencia, strategically located to connect with the rest of the country and Europe by land, sea and air.

About Rotolia

Comprehensive management

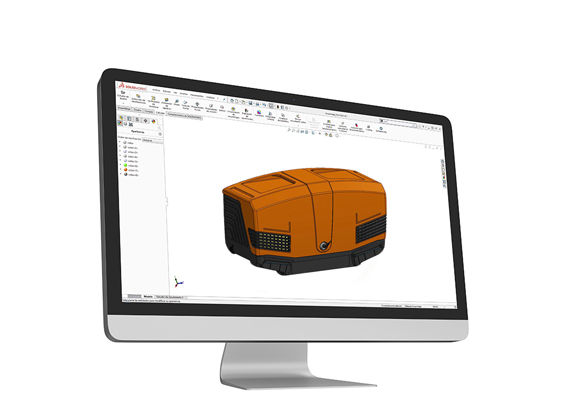

We make the design

We create 3D computer designs to define the characteristics and details of the product to be manufactured.

We create the prototype

Using 3D printing technology, we transform our customers’ ideas into physical parts in order to evaluate the product’s characteristics.

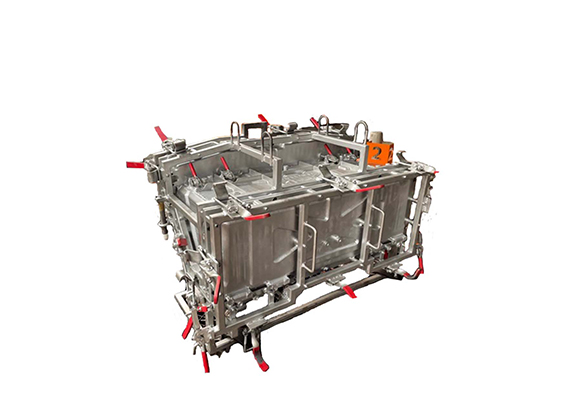

We mould and manufacture

Having cutting-edge technologies allows us to produce a mould that will give us the best possible product when manufacturing.

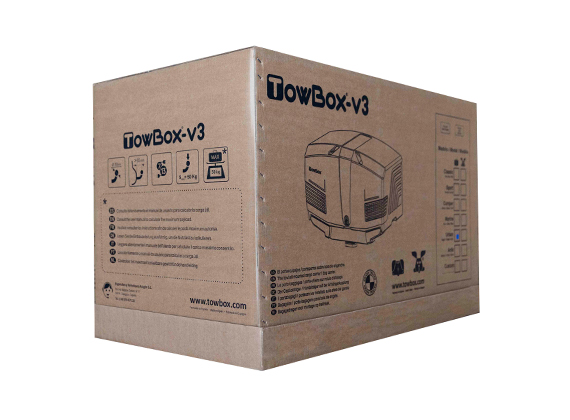

We prepare the shipment

Customised assembly service for all parts, packaged for safe shipment to the customer.

A new concept in plastic

We lead the way in using and evolving the latest technologies in the manufacture of bespoke plastic parts. Our innovation centre provides all the technological innovations necessary to ensure each project has the right solution in terms of efficiency, quality and warranty.

We offer four of the most commonly used thermoplastic technologies

Rotational moulding

Carousel 3500 and 5000 with three arms to produce parts 4800 mm in diameter and 3200 mm in height.

See moreInjection moulding

10 thermoplastic injection moulding machines from 100 to 2300 tonnes for different production volumes.

See moreThermoforming

3 machines (one-sheet, twin-sheet, and blister thermoforming) for different sizes.

See moreBlow moulding

10 blow moulding machines to produce parts from 10 grams to 14 kg for different materials.

See moreQuality plastic products

We create carefully designed bespoke products with perfect finishes.

At Rotolia, we work for different industrial sectors: automotive, urban furniture, energy, food, healthcare, aeronautics, livestock, decoration, agriculture, civil construction, logistics and packaging, gardening, etc.

See section